Potato Peeler Redesign

A redesigned potato peeler developed through rapid prototyping and form exploration. Using renders and mold-making techniques, the project considers manufacturing at scale while balancing ergonomics, usability, and everyday functionality.

Resin printing, Solid Works, Adobe Suite Silicone

ROLE

Industrial Designer

TIMELINE

TOOLS

SKILLS

Mold Making, Rapid Prototyping,

4 weeks, Fall 2024

Overview

Brief: Redesign a kitchen tool so that it can be reproduced at small and large scales informed by form models.

Manufacturing Process

Compression molding is an ideal manufacturing process for producing a potato peeler due to its ability to create durable plastic parts with precision. The peeler consists of two main components: the blade holder (top part) and the handle (bottom part), each requiring a two-part mold with guide pins for alignment. The process begins with the preparation of the charge, a pre-measured amount of raw material, which is placed in the lower half of the mold. Once the mold is closed, heat and pressure are applied, allowing the material to flow and fill the cavity. The temperature typically ranges between 250°F and 400°F, with curing times varying depending on the material. After curing, the mold cools, and the solidified part is ejected. The blade holder is designed to securely hold the metal blade, while the handle provides an ergonomic grip. Once both components are molded, they can be assembled through snapping, adhesives, or mechanical fasteners. Compression molding ensures strong, impact-resistant parts with minimal material waste, making it a cost-effective and efficient method for manufacturing potato peelers at scale.

Concept Iteration

3D paper sketches

5 volumetric, 5 linear, 5 planar models

Mid fidelity models

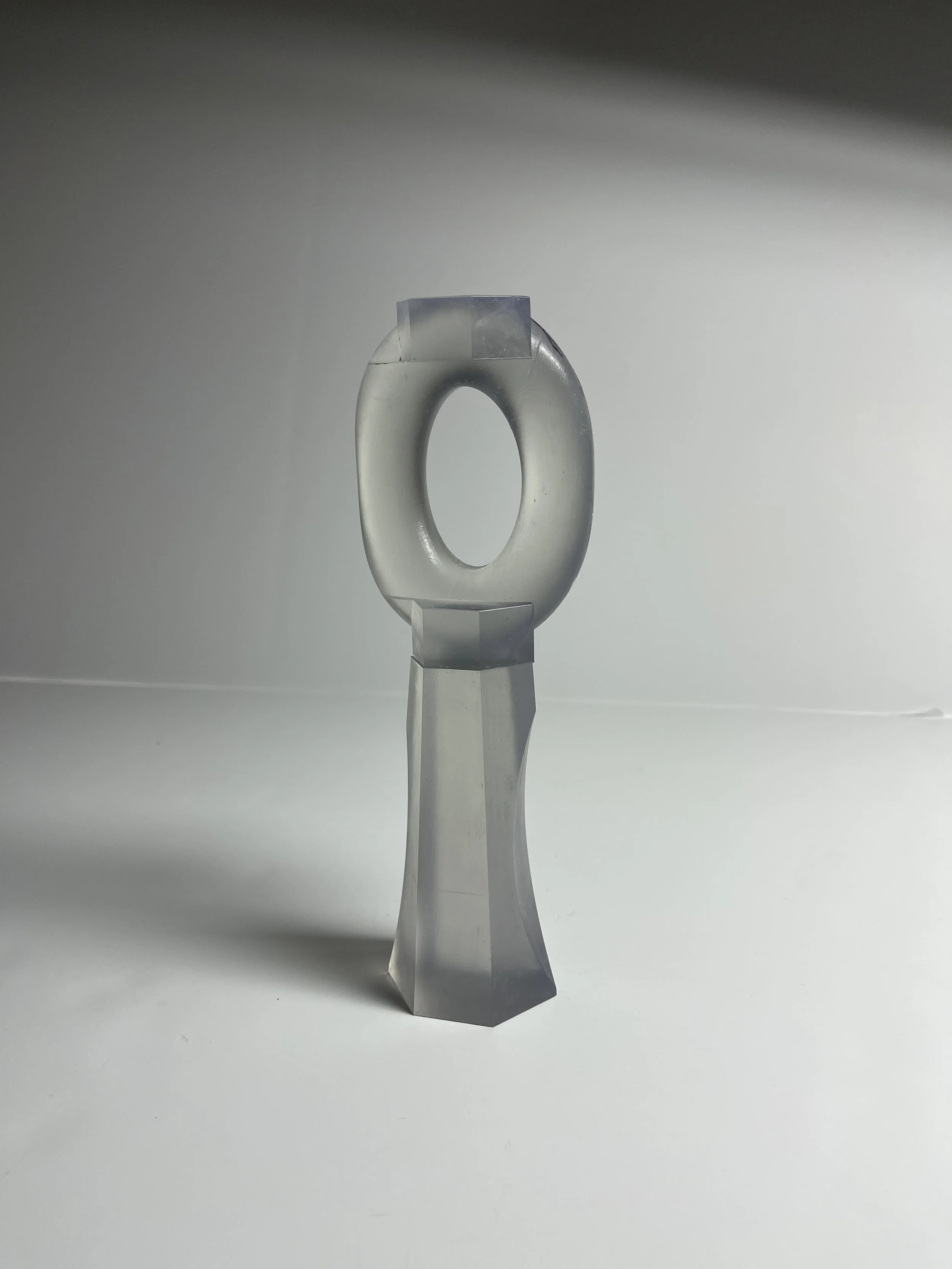

High fidelity model

Orthographic Sketches

Model represents both volumetric, and linear models from iteration designs. Handle curves are for ergonomic use and peeler top is designed for safety against blades

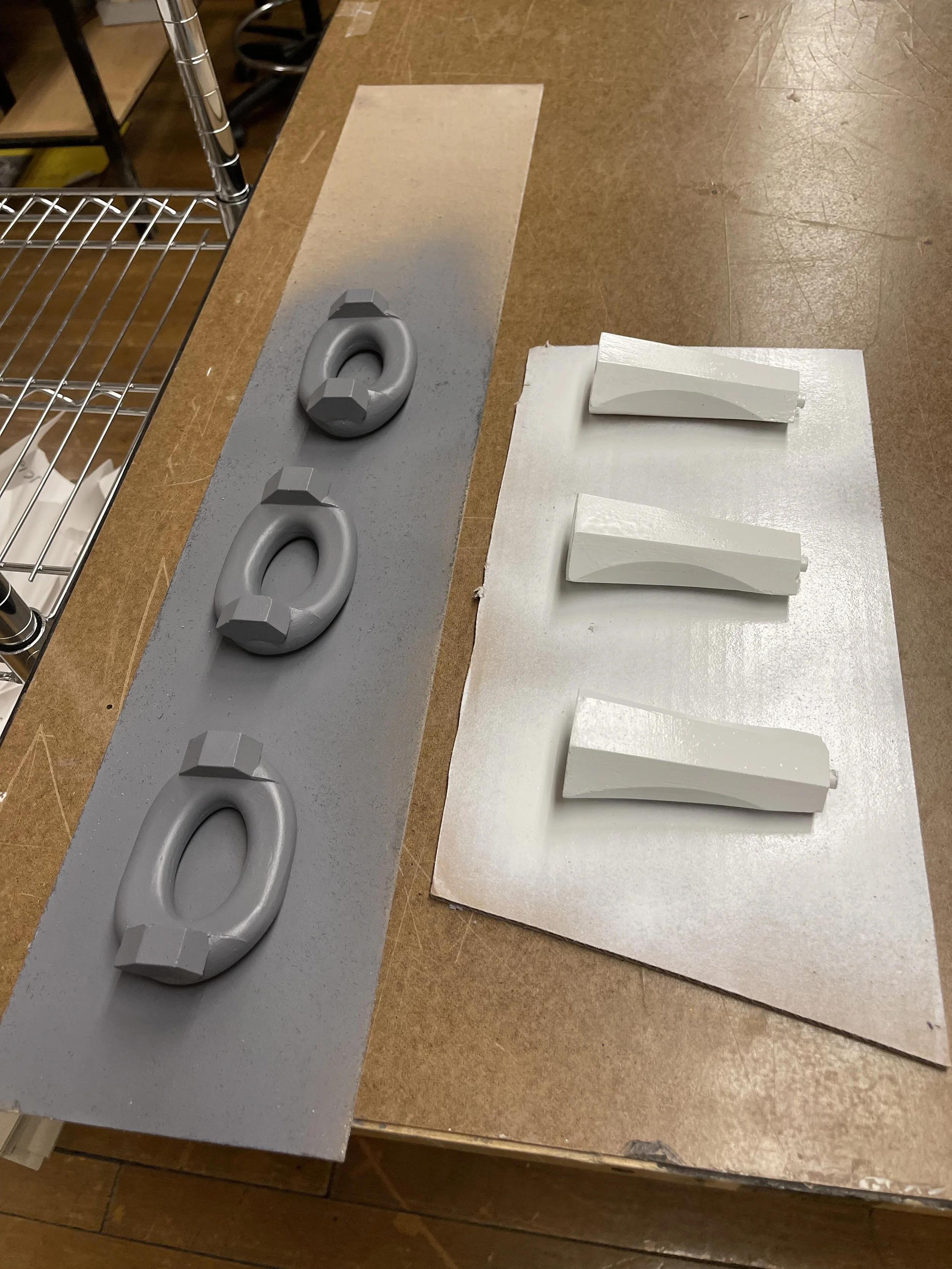

Mold Making

2 part silicon mold, filled with plaster to create 3 identical models

Design

Colors

Playful and soothing